- Adhesives & Bonding Expo Europe, 5-7 December, Stuttgart

- Important information and advice for the future of the tape business

- Adhesive Tape Market Size [2022-2029] | Industry Growth, Share, and Forecast Report by Fortune Busin

- Cookies Policy

- Privacy Policy

- What is masking tape, the use of masking tape

Email:[email protected]

WhatsApp:+86 15862668567

Address:No.188,Hengchangjing Rd,Kunshan,Jiangsu,China

Zip Code:215300

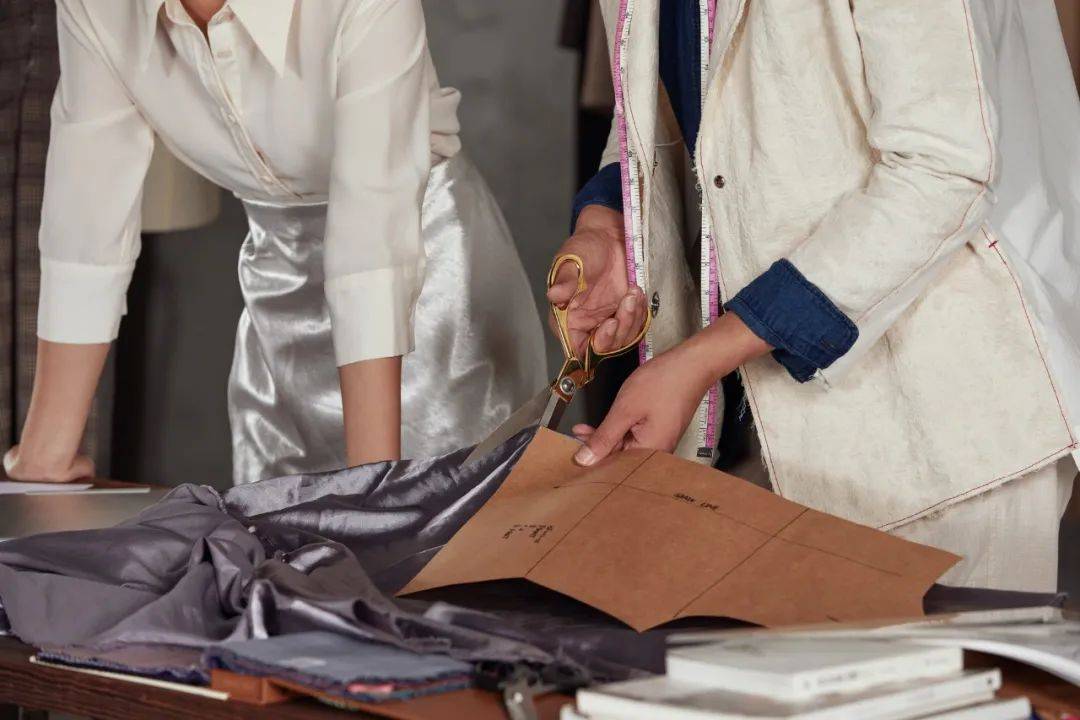

Textile & Apparel Industry

Heat seal tapes offer an ideal bonding solution for fabrics, offering manufacturers the advantages of high bond strength, flexibility, durability and solvent resistance. Heat-sealable thermoplastic tapes have the added advantage of being repositionable. When a thermoplastic adhesive is heated, it is soft and malleable. It hardens when cooled, but it can be reactivated by heating it.

Heat-sealing tapes are widely used in various special garment production lines, such as

Sportswear.

Fireman's clothes.

Weatherproof jacket.

Heat seal adhesives can be used to bond a variety of fabric combinations, including mesh and lace. The tape can be converted to various widths and customized to provide the desired finished edge that enhances the aesthetics of the finished garment. Modern garments can be assembled entirely using heat sealing tape, especially where traditional needle and thread techniques are not feasible or effective.

Benefit

Due to its unique properties, heat seal tape has excellent stretch and recovery. The advantages for apparel manufacturers don't stop there. Typically, garments made with heat-sealing tape lighter.

More durable, especially when it comes to seams.

Holds its shape better even after repeated wash and wear cycles.

Integrating heat seal tape into the manufacturing workflow can result in

Assembly is faster.

Reduce labor.

Bottom-line cost savings.

-

2018-05-18Electrical Tape Manufacturers

-

2018-05-17Duct Tape Manufacturers

-

2018-05-17Foam Adhesive Tape Manufacturers